AFRO - Autonomous Food Robot

Automating Food Assembly and Order Processing

I worked on the Autonomous Food RObot (AFRO) as part of my Robotics Capstone at Carnegie Mellon University from Fall 2022 to Spring 2023. This project involved developing a robotic system to automate food order processing and assembly, addressing the labor shortages and inconsistencies commonly experienced in fast-casual restaurants. The AFRO system automates key components of the food assembly line, increasing efficiency while allowing employees to focus on higher-value tasks.

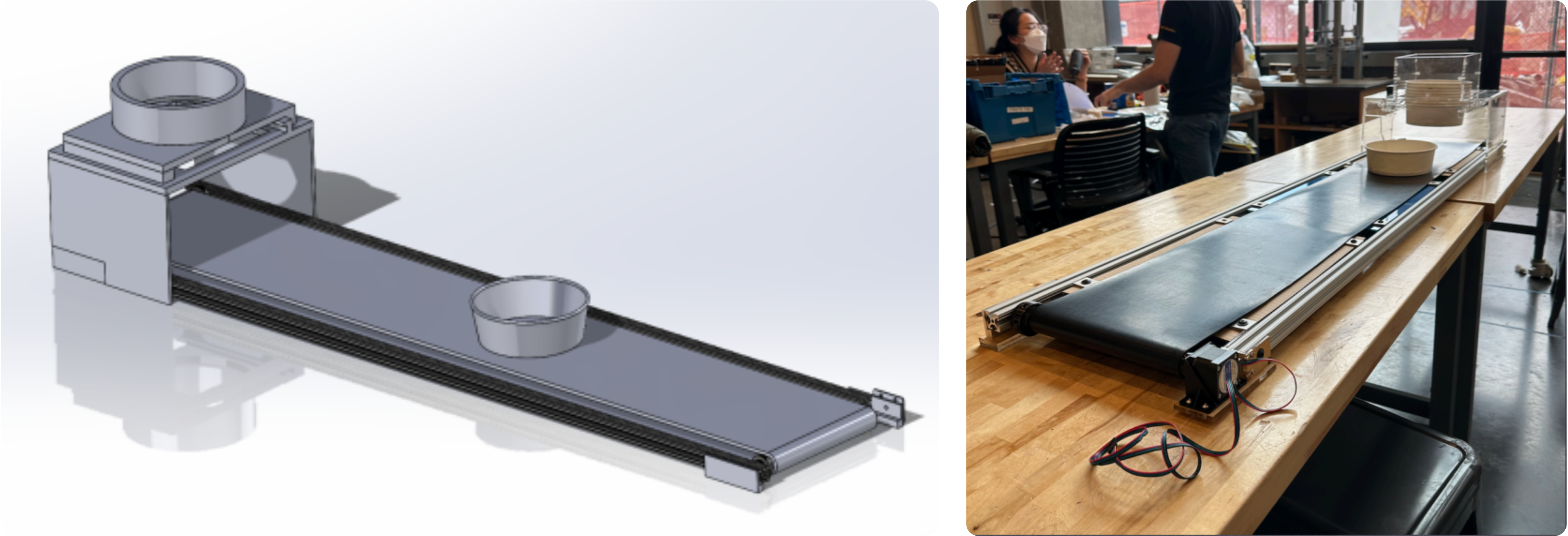

The AFRO system was designed to streamline food preparation in fast-casual restaurants by automating the process from order intake to food assembly. The system included a user-friendly tablet-based interface for customers to place orders, which were processed via a backend API and database. The robotic assembly line featured a bowl dispenser that placed individual bowls onto a conveyor belt, guiding them through sequential stations where food ingredients were dispensed with precision using auger-based mechanisms for consistent portions.

My primary contributions focused on the mechanical design, fabrication, and integration of the bowl dispenser and conveyor belt subsystems. I developed detailed CAD models and led the assembly of these components, ensuring compatibility and structural stability. During testing, I identified and resolved critical issues, such as bowl misalignment and belt stalling, by refining the geometry and replacing heavy rubber belts with lightweight synthetic alternatives. These modifications enhanced the reliability of the dispensing and transportation processes.

The final system demonstrated robust performance, successfully handling multiple concurrent orders and receiving positive feedback for its efficiency and accuracy. The project showcased the potential for robotics to address labor shortages and streamline restaurant operations, achieving significant reductions in assembly time. This experience strengthened my skills in system integration, mechanical design, and collaborative problem-solving, reinforcing my commitment to creating practical robotic solutions for real-world applications.