Samsung Smart Factory Robotics

Enhancing Smart Factory Adaptibility with Robotic Gripper Integration

I worked as a Robotics Software Intern with the Smart Factory Robotics Software Team at Samsung Electronics from June 2023 to August 2023.

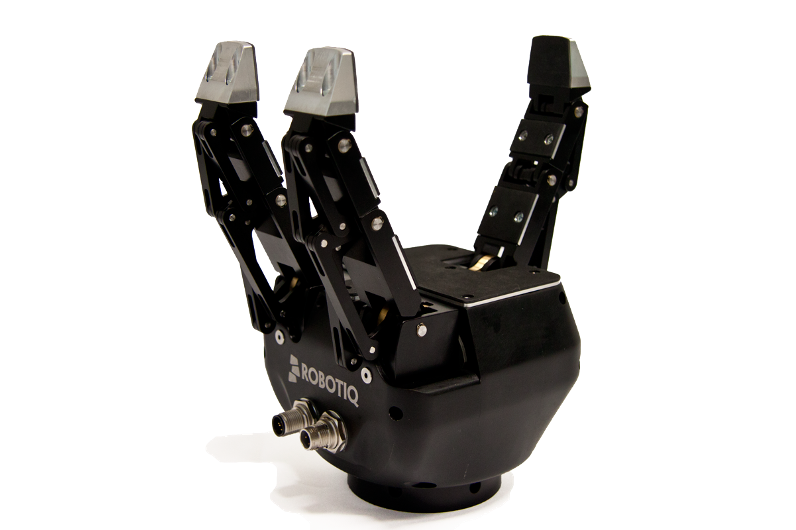

This project showcases the integration of a Robotiq three-finger gripper with Samsung’s industrial 6 DOF robotic arm, aimed at enhancing smart manufacturing processes through improved adaptability. The following sections outline the core components of the project.

- Custom Hardware Design: Developed a secure, durable gripper mount to attach the Robotiq gripper to the robotic arm.

- Ethernet Communication Protocol: Established a communication interface for controlling the gripper directly from the manipulator’s control box.

- Control Software Development: Implemented user-friendly control functions to facilitate accurate and intuitive pick-and-place operations.

Due to company privacy policies, project-specific images and media cannot be published.

These upgrades improved precision, adaptability, and efficiency, enabling the robotic arm to handle a wider range of objects and perform more complex tasks. This work strengthened my expertise in modular hardware design, real-time communication protocols, and user-centered robotics software. It also demonstrated the potential for adaptive robotic solutions to optimize smart factory operations and laid the groundwork for future gripper research work.